Engineered for Goosebumps

September 2, 2021

While most brands rely on three drivers or more, each one taking care of their part of the frequency spectrum, Sennheiser believes in the one-driver principle. Based on this philosophy, we developed our unique 7 mm TrueResponse transducer which can be found in various forms throughout Sennheiser’s professional and consumer-focused in-ear ranges.

The single most important technical feature in your headphones might very well be the transducers. These are literally the technical heart of your phones. Like tiny loudspeakers, the transducers convert electric signals into soundwaves you can hear. Sennheiser's TrueResponse transducer is designed to bring the listener as close to the source as possible.

An engine that allows us to create fantastic sound

Instead of a multi-driver system that introduces phase incoherence and unwanted distortion, we developed our 7 mm TrueResponse transducer. The deployment of a single, high-performance dynamic driver completely avoids the sonic obstacles introduced by alternative multi-driver arrays: phase incoherence and the subsequent distortion borne from the overlapping frequency bands of the driver-crossover mechanism.

Complex Simplicity

Sennheiser’s TrueResponse transducer is one of the world’s smallest within its category. It consists of a single high-performance dynamic driver, with a diaphragm of only 7 mm in diameter to cover the entire frequency spectrum. A custom-made magnet system with triple-channel ventilation significantly reduces the distortion factor. Even at high sound pressure levels, the sound remains clean and free of distortion.

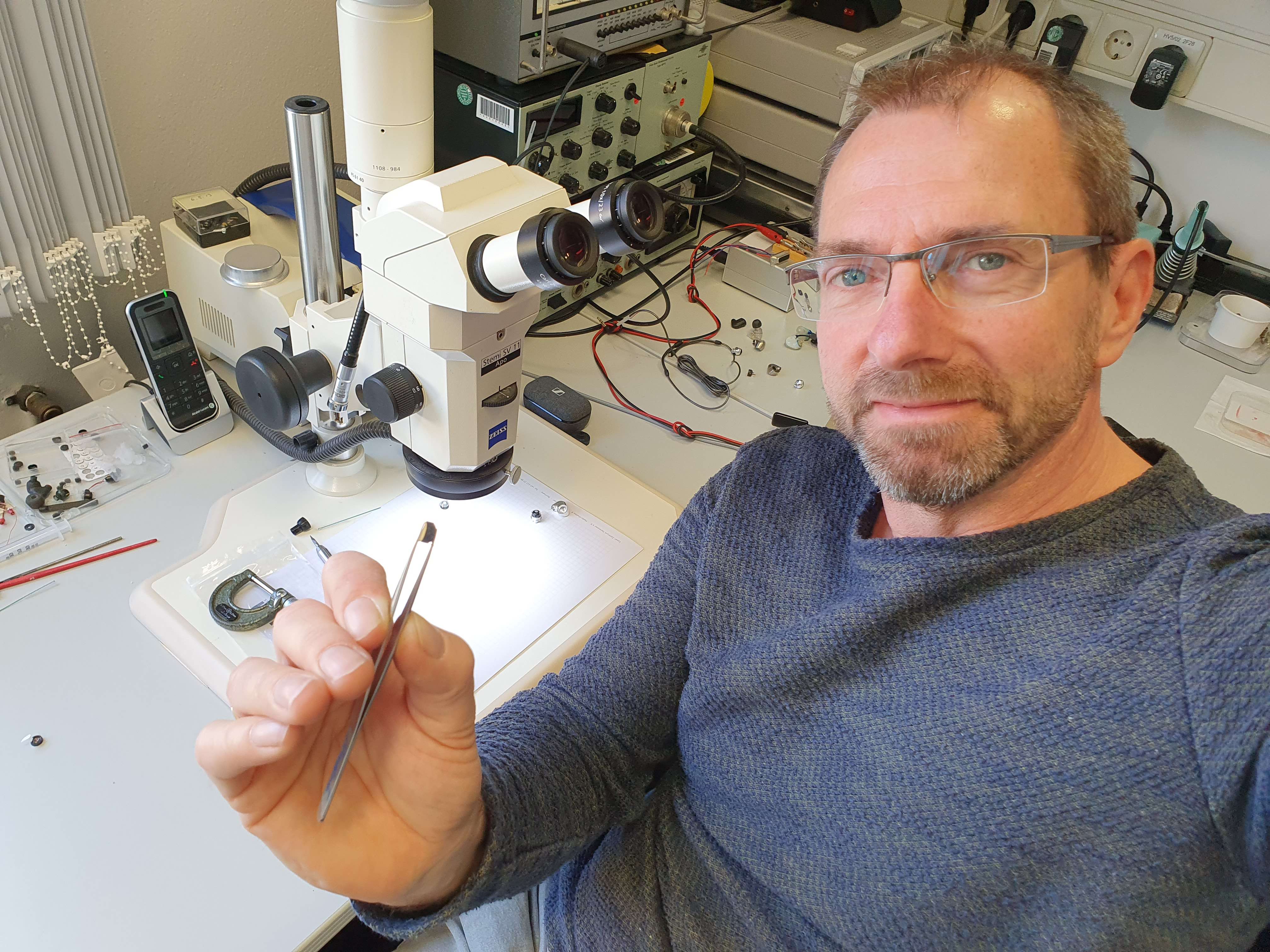

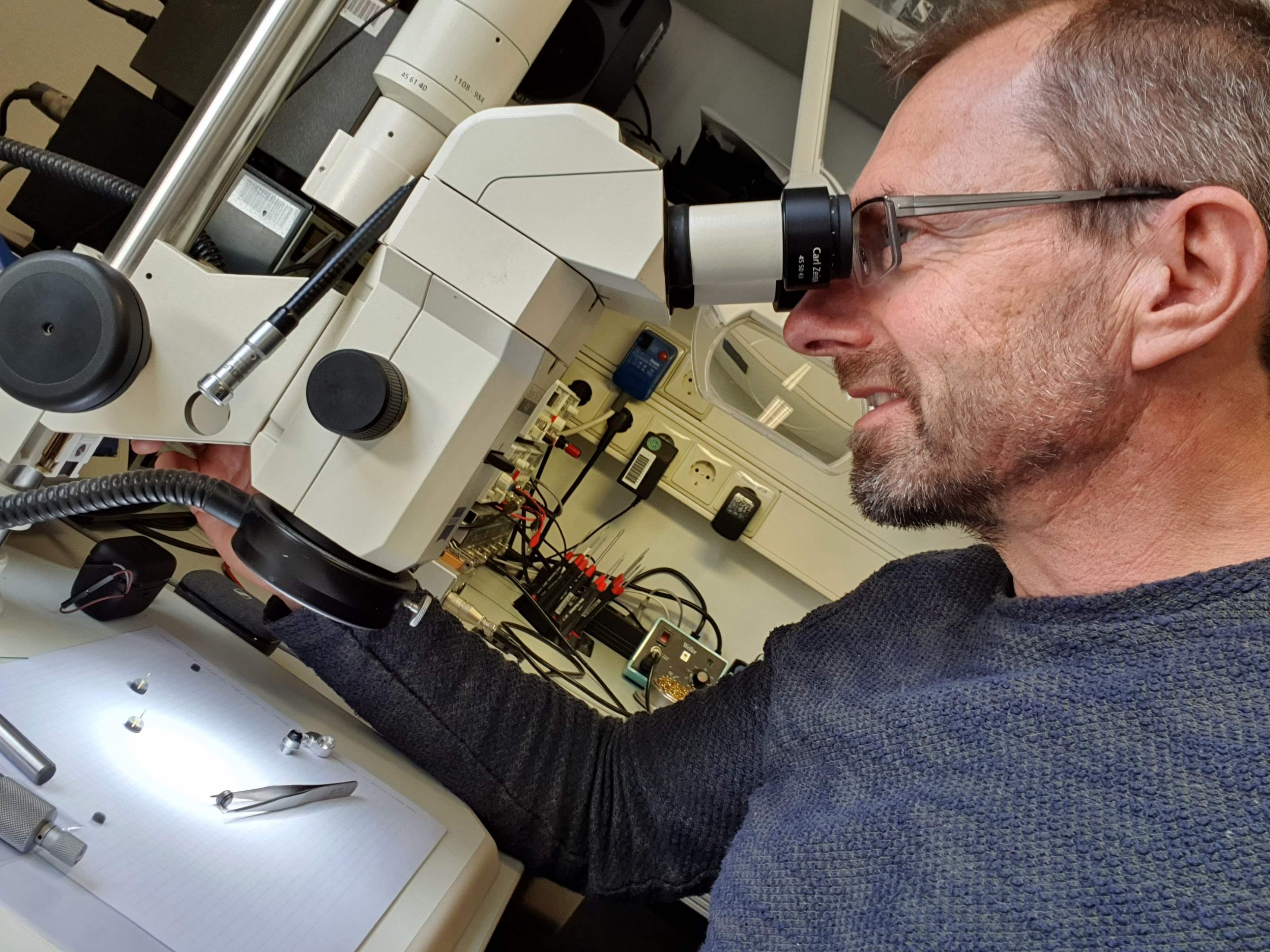

Obsessed with Sound: Andre Michaelis

We sat down with acoustic engineer Andre Michaelis from Sennheiser’s development team for a conversation about the 7 mm TrueResponse transducer.

It is known as one of the smallest transducers in the audio world. How did you come up with the idea for this innovative piece of engineering?

“We are all obsessed with sound in this company. I listen to all types of music, from classic to techno, and when I hear music, I want to hear it clear and good. It must be natural. This is what you get with these transducers.”

André Michaelis says and continues,

“I was team leader for a small group of engineers looking to develop a transducer for the IE 800, our first audiophile in-ear headphones. We built the first transducers by hand, which was very expensive. The feedback from our customers was very positive though, so we went back to the lab, five guys, three days per week, and worked on a concept for an optimized production line for this small transducer. It was a very cool job. We asked our CEO, Andreas Sennheiser, if we could show him the concept and he liked it. From there, the 7 mm TrueResponse transducer you see today came into production.”

How does this technology differentiate from what other brands are doing?

“Most other audio brands use technology based on the same principles that you find in hearing aids. I have seen in-ear headphones which have up to 12 transducers. A few even have more. What makes our one-driver principle unique is the way we balance everything. In our quest for clear sound we have taken away all electronic parts and crossovers. This opens the finest frequencies, gives a clearer overview and, most importantly, more goosebumps. They might look simple on paper, but they are extremely complex.”

You mentioned that you had to set up a whole new production line to build these transducers. How are they made?

“That’s right, we build the transducers right here in Wedemark where they were also developed. As mentioned, they have a very small airgap for the coil. We cut the holes for the ventilations with lasers and we developed our own magnet system. You must handle very small parts; we’re talking a few millimeters that need to fit together perfectly. We press the metal parts together and put them in the mold. We don’t need glue. The machines we use for this are the biggest machines we have in Wedemark. The biggest machines to produce the smallest parts. We have three robot arms in each of our two molding machines – and we are really happy with their work.”

Most importantly maybe, how do these transducers sound?

“You cannot say that there is a specific 7 mm TrueResponse transducer sound. You should more see them like an engine that allows you to create fantastic sound. We modify them for each of our models, which all have their own distinctive sound and purpose. If we use these transducers for an in-ear monitor for vocalists, we use a specific damping material that enhances vocals. You have more stage in our large headphones, while in-ears are perfect for commuting and travelling. Transducers themselves do not bring much flavor to the sound, the entire headphone does. The transducer is a technical heart, but to feel the soul you need a holistic approach and take every aspect of the entire headphone into consideration.”